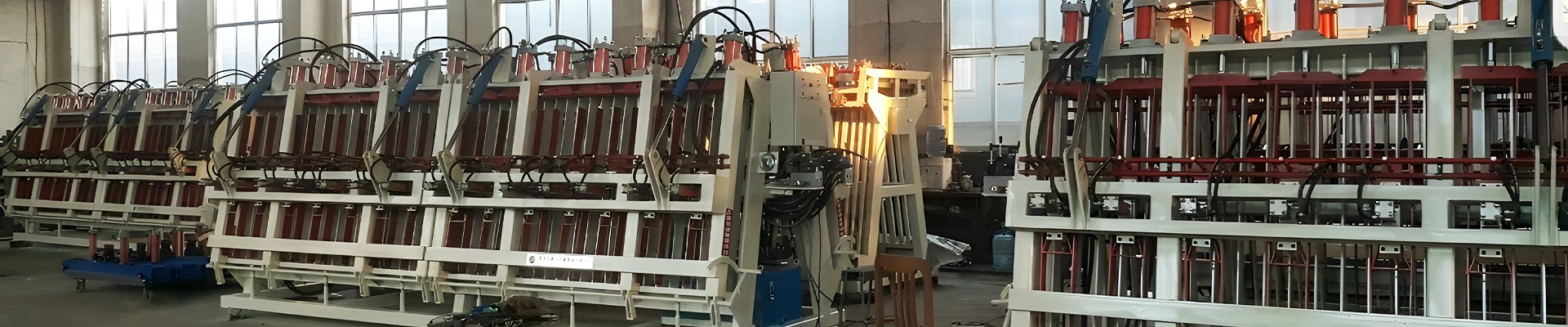

The flip type clamp carrier machine of Qingdao Chuangxinyuan Machinery Manufacturing Co., Ltd. plays an important role in the splicing of solid wood panels. It is mainly used to splice solid wood panels of different sizes and thicknesses to form large-area panels, which is crucial for furniture manufacturing and woodworking industries. The following are the main functions and advantages of the flip type clamp carrier machine in solid wood panel splicing:

Strong flexibility: The flip type splicing machine can handle various specifications of boards, including large boards, small boards, thin boards, and thick boards. This flexibility allows it to adapt to different splicing needs and meet the requirements of various furniture and woodworking projects.

Improving efficiency: Through mechanized flipping and splicing processes, the clamp carrier machine significantly improves the efficiency of splicing. Compared to traditional manual splicing methods, machine operation is faster and more precise, saving time and labor costs.

High splicing quality: The flip type clamp carrier machine can ensure the precise splicing position of the board and smooth joints. This helps to improve the quality of the final product, reduce defects at the joints, and make the spliced board more stable and aesthetically pleasing.

Easy to operate: Modern flip type clamp carrier machines are usually equipped with intelligent control systems and automation functions, making operation relatively simple. Operators only need to make basic settings and adjustments, greatly reducing the difficulty and skill requirements of operation.

Strong adaptability: For different types and thicknesses of boards, the flip type splicing machine can flexibly adjust the splicing parameters. This adaptability enables machines to process various types of solid wood panels, whether they are cork or hardwood, and achieve efficient splicing.

Overall, the application of flip type clamp carrier machines in solid wood furniture factories has significantly improved the efficiency and quality of splicing, making the production process more efficient and precise.